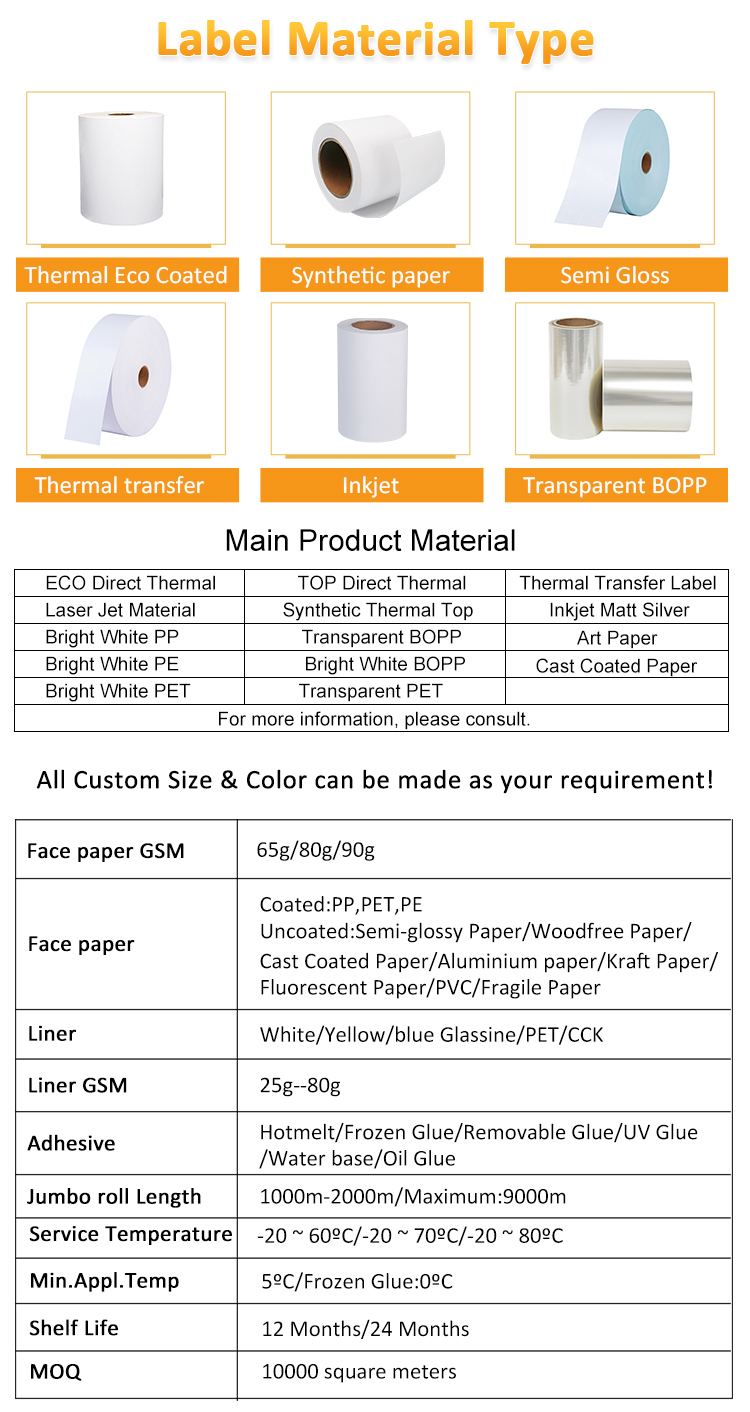

thermal label jumbo roll raw material self adhesive

About this item

Thermal Jumbo Label Roll is a high-performance self-adhesive label paper, which is manufactured with the most advanced technology and has the advantages of high temperature and resistance, folding resistance, and ultra-low deflection rate. It is naturally moisture-resistant, can withstand high-pressure dipping for printing effects, and can be used outdoors and in low-temperature environments.

Thermal Jumbo Label Roll can be used in various applications, including logistics information management, electronic labeling, inventory management, hospital process management, process integration, safety management, trade management, business analysis and more. They stick easily, are easy to maintain, are highly durable and heat resistant, and they can also be printed easily with excellent reliability and printing performance.

Thermal Jumbo Label Rolls offer many advantages, including excellent printing results, reliable sticking, temperature stability and durability, folding resistance, reliable performance, stain and moisture resistance, ultra-low deflection rate, temperature and humidity can be control and resistance elements and so on.

Why Choose Thermal Jumbo Label Roll? Because they are designed for existing commodities and industries, they can meet your changing packaging requirements, have excellent reliability, performance and printing performance, focus on service, cost-effective, sustainable application and installation, and lightning fast deliver.

Manuals

| Self-adhesive product manuals | ||||

| Product Code | SH7260 | |||

| product name | 72g economic three-proof / water glue / 60g white grid | |||

| face material | 72g economical three proof thermal paper | |||

| substrate | 60g white glassine silicon paper | |||

| glue | Ordinary water glue | |||

| Technical indicators: | ||||

| Classification | project | index | unit | method |

| face material | Quantitative | 72±10% | g/m2 | GB/T 451.2-2002 |

| thickness | 80±10% | µm | GB/T 451.3-2002 | |

| BaiDu | ≧80% | % | GB/T 7974-2002 | |

| water proof | ≧50% | % | GB/T 28210-2011 | |

| oil-proof | ≧60% | % | GB/T 28210-2011 | |

| Color rendering density | ≥1.10 | % | GB/T 28210-2011 | |

| substrate | Quantitative | 60±10% | g/m2 | GB/T 451.2-2002 |

| thickness | 53±10% | µm | GB/T 451.3-2002 | |

| Tensile Strength Longitudinal | ≥5.2KN/m | KN/m | GB/T 12914-2018 | |

| glue | Ring tack | ≧14 | N | FTM9 |

| 90° peel force | ≧7 or paper torn state | N/25mm | FTM2 | |

| 180°30m/min high-speed release force | ≦35g | g/㎡ | FTM1 | |

| Minimum labeling temperature | 10℃ | |||

| Operating temperature | -15℃~65℃ | |||

| Product Description: | Produced with high-quality raw materials, high whiteness, clear printing, excellent waterproof effect, and good thermal image preservation performance. | |||

| Printing and Processing: | Can be used for printing with most traditional printing methods. Due to the heat-sensitive nature of the product, processing environments over 50°C should be avoided. Inks containing alcohol or volatile organic solvents may damage the heat-sensitive layer. For flexographic printing, UV or water-based inks and varnishes are recommended. It is recommended to test the ink before printing. It can be used for non-direct contact labeling of products such as food, medicine and cosmetics. | |||

| Store and save: | Should avoid long-term exposure to environments above 50 ℃ or direct sunlight. The validity period is 1 year under the condition of temperature 23±2℃ and relative humidity 50±5%. Products that have exceeded the validity period can still be used after passing the inspection. |

|||

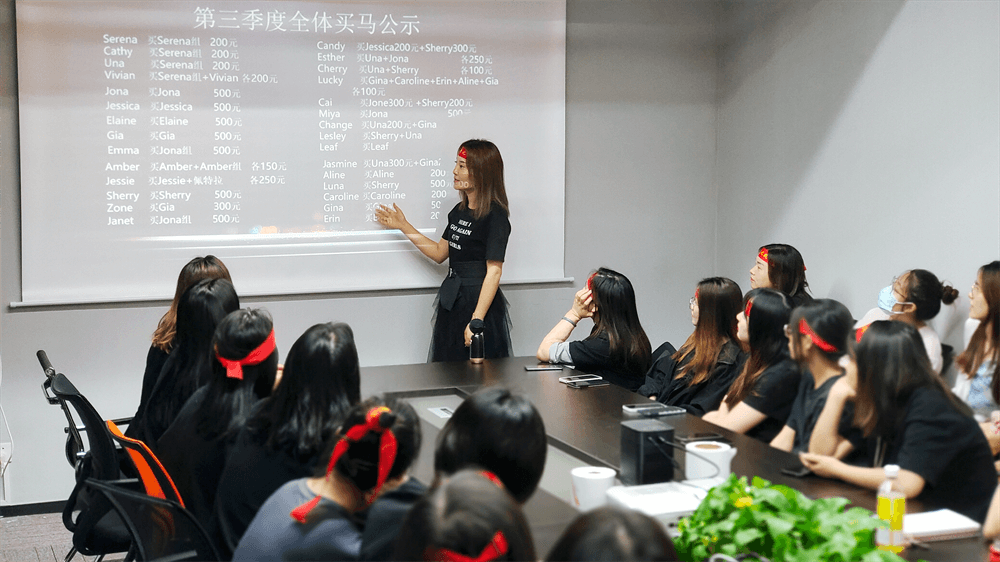

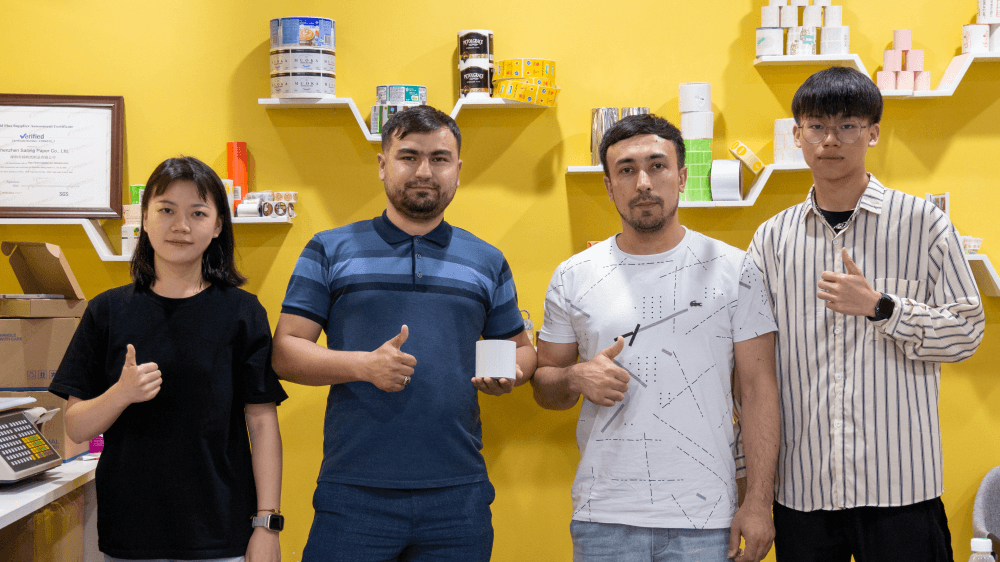

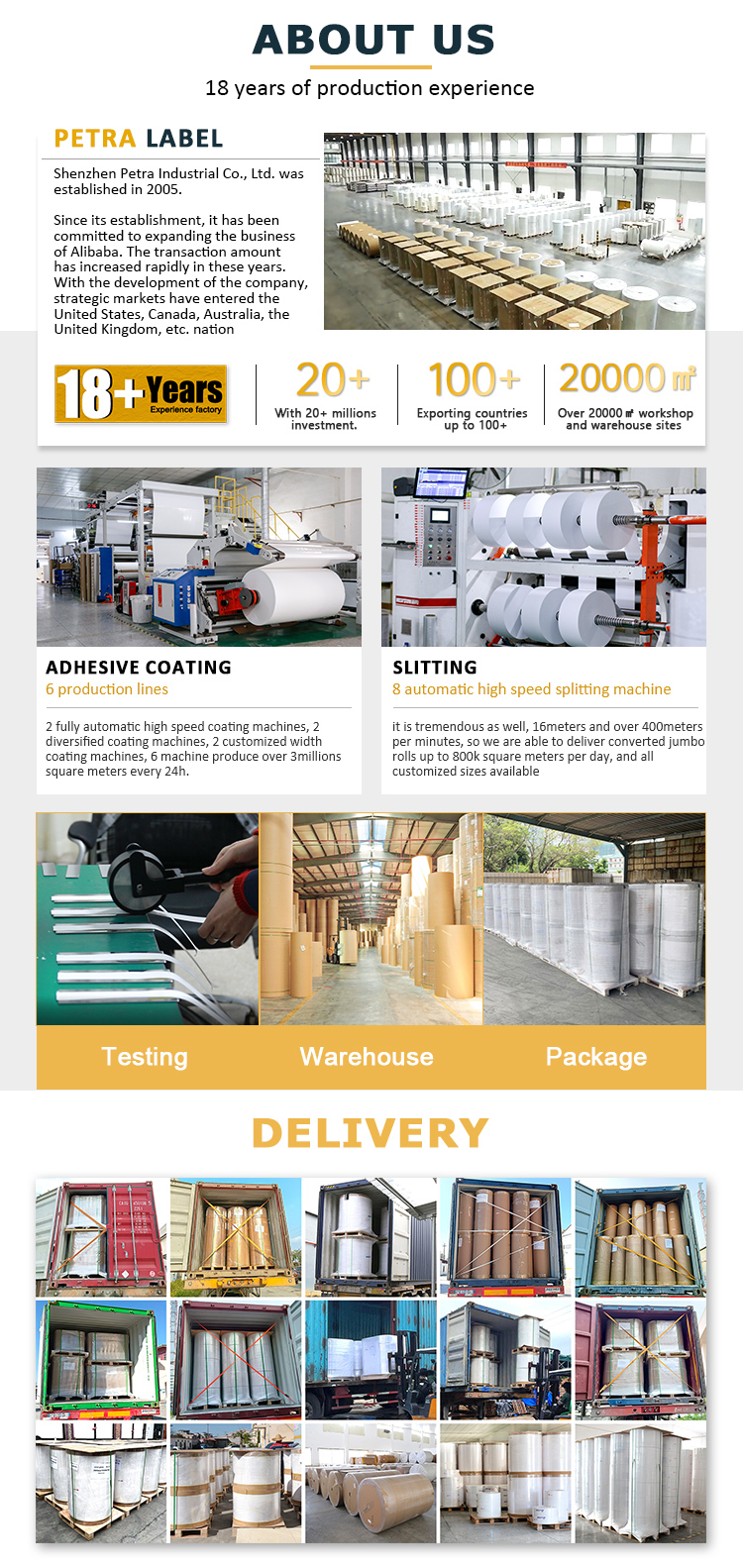

Office image

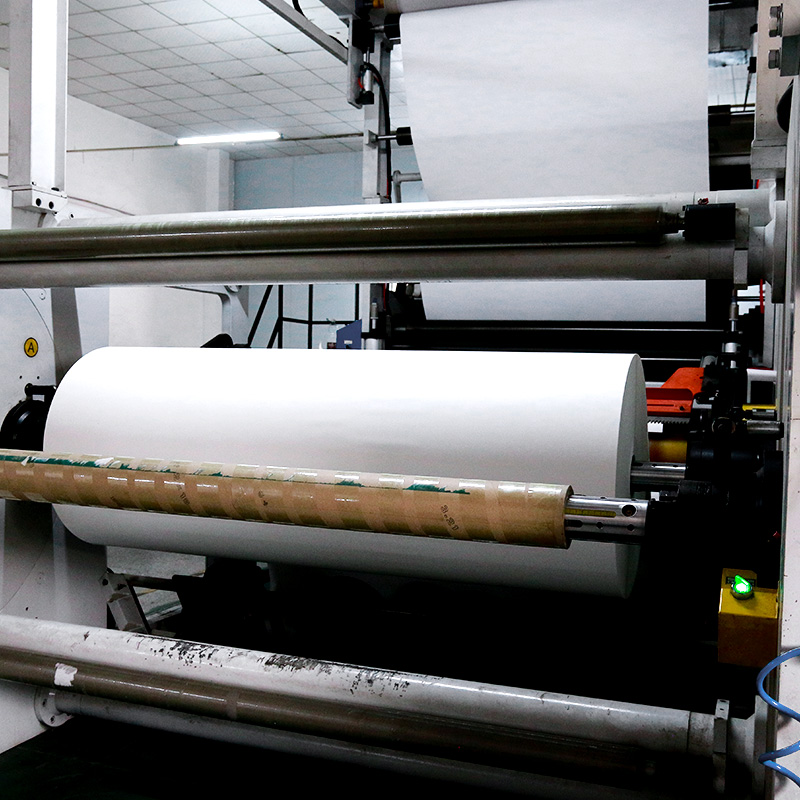

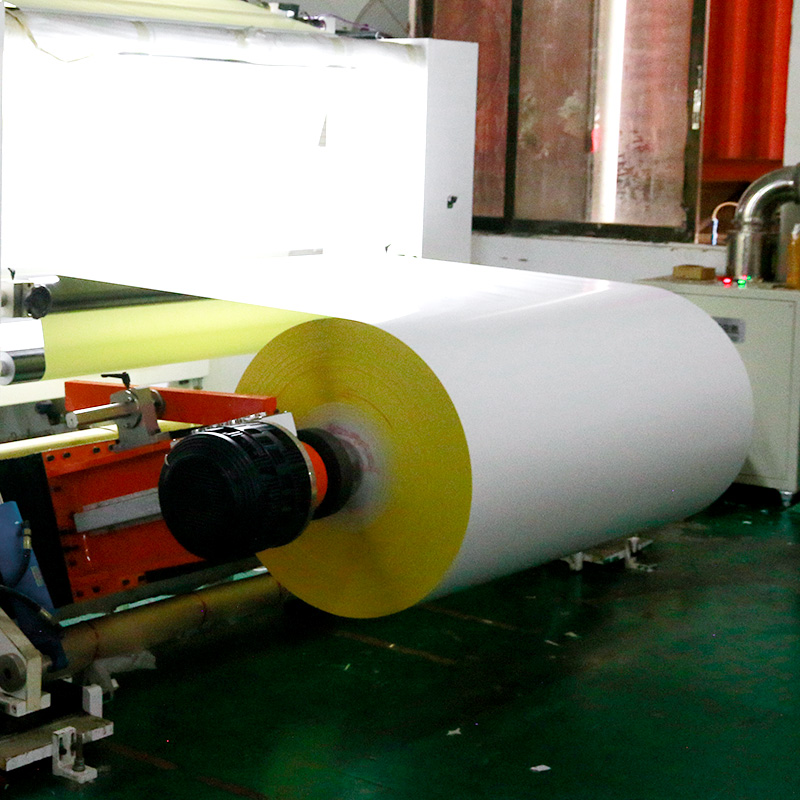

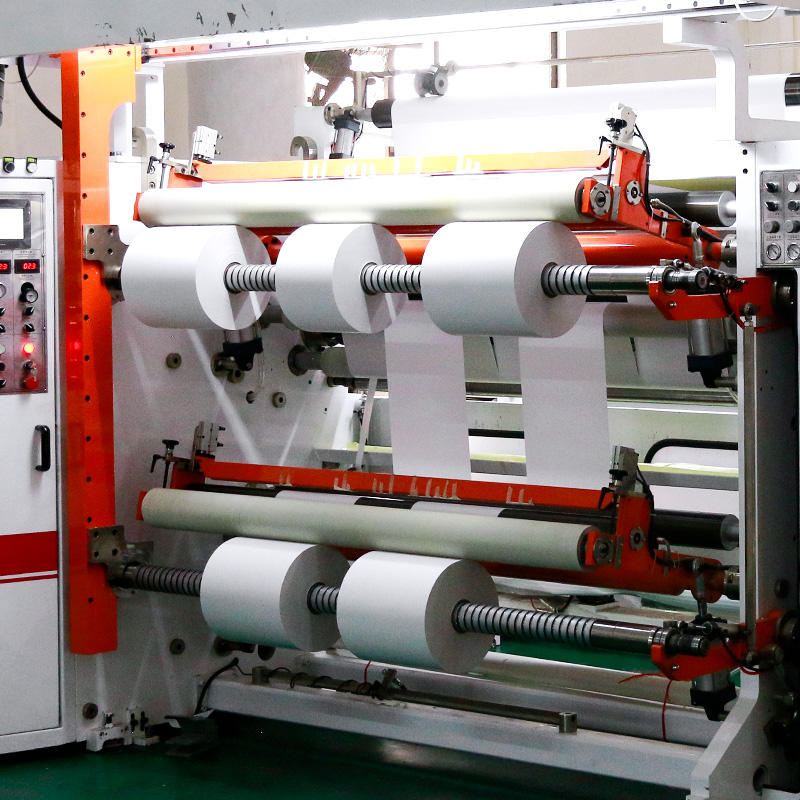

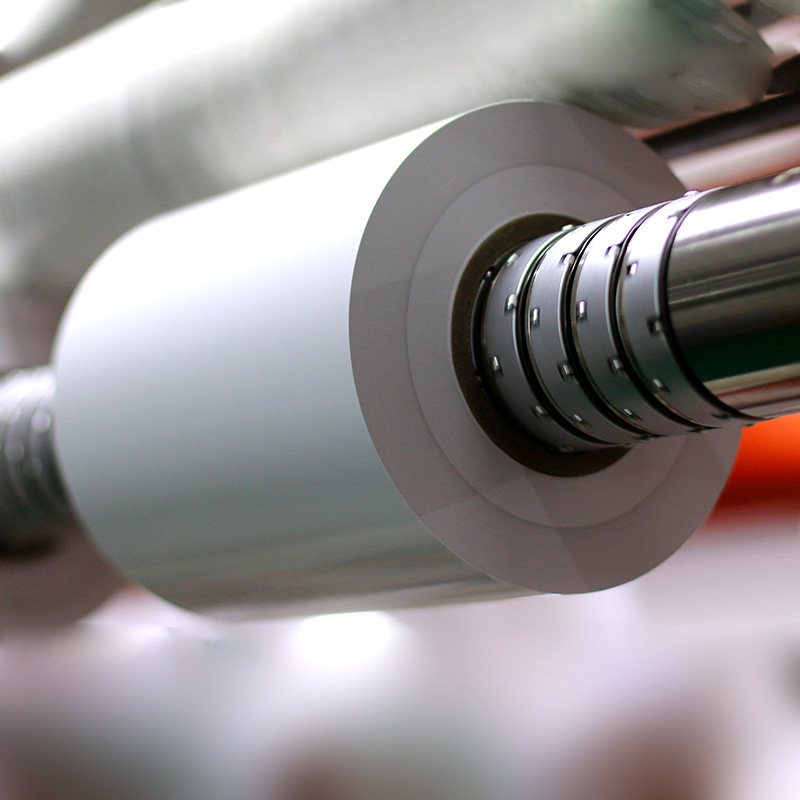

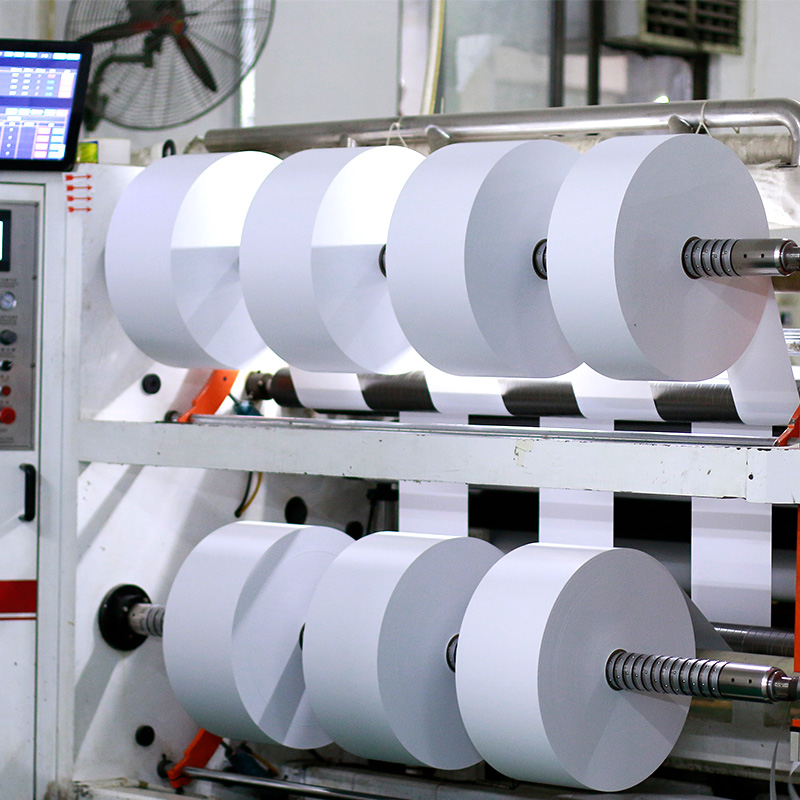

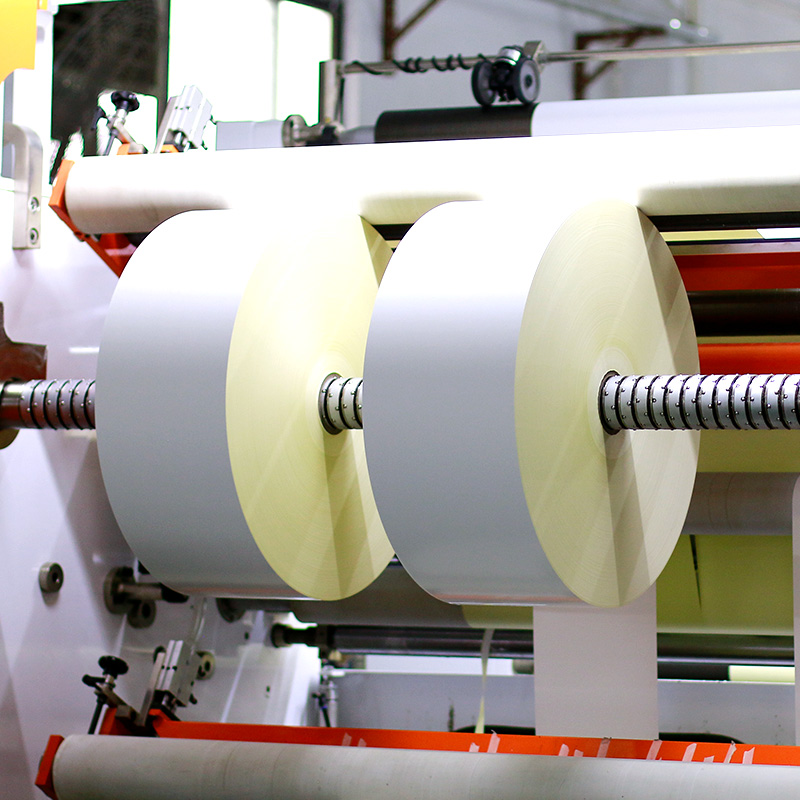

Factory image

-50g-White-Glassine-silicon-paper(10-15g).jpg)